Insulators installed on HVDC lines have to sustain very unique and specific stress conditions associated with the unidirectional electrical field and current flow that are generating ionic migration, thermal runaway, pollution accumulation and corrosion of metal fittings.

To achieve an optimum performance in DC and to cope with these 4 specific Direct Current constraints, Sediver pioneered, as early as the mid 1980’s, an exclusive DC insulator that combines:

- a high resistivity toughened glass (HRTG) chemical composition able to block the ion flow

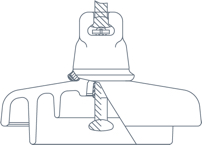

- an optimized insulator design with an increased leakage distance to enhance the pollution performance and a protection of the metal fittings against electrolytic corrosion

- a special manufacturing process that produces a very high purity of glass, which makes it less sensitive to ionic accumulation

This development has largely contributed to establishing a high-performance benchmark in the industry, including specific criteria later on introduced in IEC 61325 which is still the only international standard describing HVDC performance requirements.

Range

The specific conditions of DC applications require that the insulator be designed to reduce the risk of excessive dust accumulation resulting from unidirectional electric fields. In DC application Sediver recommends the selection of glass profiles with self-cleaning properties of reduced pollution build-up.

Recommended profiles:

FOG types profile

In heavy polluted areas

Open profile

In desert areas

Outerib profile

In heavily polluted areas with solid pollution

Mechanical rating

From 70 kN up to 840 kN

Sediver extensive HVDC worldwide experience

- 50+ years of experience in HVDC applications

- More than 11 million Sediver insulators have been installed all around the world on the most prestigious HVDC transmission lines up to 800 kV

2. ± 260 kV DC, Canada, Vancouver Islands 42km, 1967

3. ±200 kV DC, Italy-France, Corsica-Sardinia-Italy 264 km, 1967/1992

4. ± 500 kV DC, USA, Pacific Intertie 1 360 km, 1969/2014/2017-2019

5-6-7. ±450&500 kV DC, Canada, Kettle Winnipeg Nelson River, 2×870 km Bipole I, II,& Bipole III, 1.364 km, 1972 & 2014-15

8. ± 250&350 kV DC, Denmark-Norway, Skagerrak 217 km, 1&2;3 1975/1993

9. ±500 kV DC, USA, Dickinson – Coal Creek 687km, 1978

10. ±500 kV DC, Mozambique, Cahora Bassa 1 420 km, 1978

11. ± 500 kV DC, USA, New England 85 km, 1984

12. ± 450 kV DC, Canada, Quebec- New England, 1 100 km, 1988

13-14. ±600 kV DC, Brazil, Itaipu 1 & 2, 2 x 800 km, 1984/87

15. ±500 kV DC, India, Rihand Dadri 814 km, 1987

16. ±500 kV DC, Finland-Sweden, Fenno Skan 1&2 136 km, 1988/2009

17. ±350 kV DC, New Zealand, North South Island 535 km, 1990

18. ±500 kV DC, India, Chandrapur Padghe, 752 km, 1997

19. ±400 kV DC, Italy-Greece Interconnection, 110 km, 1999

20. ±500 kV DC, China, Tianshengqiao – Guangzhou 1 050 km, 2001/2004

21. ±500 kV DC, China, Guizhou – Guangdong 1 & 2 2007 km, 2003

22. ±500 kV DC, China, Yunnan – Guangdong 1 418 km, 2008

23. ±500 kV DC, India, Ballia Bhiwadi 780 km, 2008/2009

24. ±500 kV DC, China, Deyang – Baoji 534 km, 2009

25. ±500 kV DC, China, Gezhouba-Shanghai 1 929 km, 2009

26. ±800 kV DC, India, Biswanath Agra 1 825 km, 2010/11/12

27. ±800 kV DC, China, Jinping-Sunan 2 089 km, 2011

28. ±800 kV DC, China, Nuozhadu-Guangdong 1 413 km, 2012

29. ±500 kV DC, China, Xiluodu-Guangdong 1 251 km, 2012

30. ±300 kV DC, Sweden, South-West Link – the Southern part, 2012

31-32. ±600 kV DC, Brazil, Rio Madeira I&II, 2 x 2 500 km, 2012/13

33. ±500 kV DC, Congo DR, Inga-Shaba 1 700 km, 2013/2017

34. ±500 kV DC, Canada, Eastern Alberta, 500 km, 2013

35. ±800 kV DC, China, Hami-Zhengzhou 2 208 km, 2013

36. ± 350 kV DC, Labrador-Newfoundland – Muskrat Falls,1 300 km, 2014

37. ±500 kV DC, China, Jinzhong-Guangxi, 577 km, 2015

38. ±500 kV DC, China, Guanyinyan DC, 700 km, 2015

39. ±800 kV DC, Brazil, Belo Monte I, 2 000 km, 2015-17

40. ±200 kV DC, Canada, Maritime link, 2016

41. ±500 kV DC, Ethiopia-Kenya, Interconnection, 1 045 km, 2016-17

42. ±800 kV DC China, Dianxibei, 1 928 km, 2017

43. ±800 kV DC China, Ximeng-Taizhou, 1 620 km, 2017

44. ±800 kV DC, Brazil, Belo Monte II, 2 300 km, 2017

45. ±800 kV DC, China, Zhalute-Qingzhou, 1 320 km, 2017

46. ± 800 kV DC, China, Shaanbei-Wuhan, 1 135 km, 2019

47. ±800 kV DC, China, Qinghai-Henan, 1 575 km, 2019

48. ±800 kV DC, China, Wudongde-Guangxi, 1 490 km, 2019

49. ±500 kV DC, China, Yunnan-Guizhou Interconnection, 1283 km, 2019

50. ±500 kV DC, Tajikistan-Afghanistan, Sangtuda to Deh Salah, 162 km, 2020

51. ±800 kV DC, China, Baihetan-Jiangsu, 2269km, 2021

52. ±800 kV DC, China, Baihetan-Zhejiang, 2193 km, 2021

Case studies

English

English