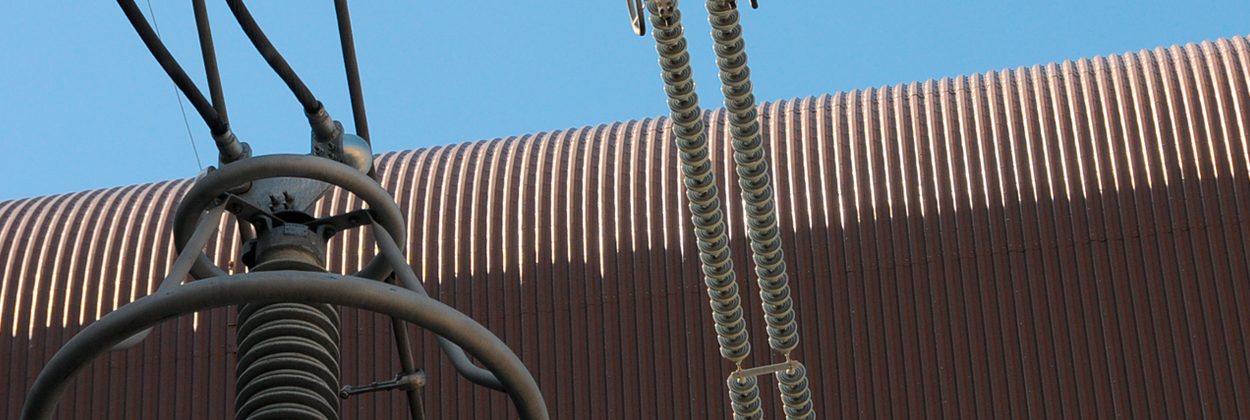

Adressing major pollution problems on a 500 kV line extracting power from a power plant

Customer challenge

When a nuclear power plant is located on a coast, salt fog and salt deposits on the insulators are a major problem. In this case, the utility was facing two constraining options: either to conduct live line work to wash the strings with the line energized or to shut down the facility to allow cleaning of the insulators.

What we delivered

Sediver proposed to combine the most appropriate insulator shape (optimizing the possible leakage distance) to the use of silicone coating. Since the installation of this solution the line remains operational with no need for washing and no plans for an outage during the fuel life cycle. While originally the goal was to avoid washing between two consecutive refueling operations, the insulators have now been through multiple cycles without any need for maintenance.

English

English